Mesure d'humidité en ligne sans contact pour les solides

ENVEA M-Sens NIR est une technologie de spectroscopie proche infrarouge (NIR). Utilisant une solution logicielle intelligente, le M-Sens NIR fournit une mesure d’humidité instantanée, précise et non destructive, sans contact.

La spectroscopie proche infrarouge (NIR) utilise la transmission et l’absorption de la lumière pour mesurer l’humidité dans un échantillon de matériau.

M-Sens NIR peut être utilisé sur différents types de matériaux, il s’agit d’une mesure d’humidité en ligne sans contact.

Étant donné que le NIR pénètre plus profondément dans les matériaux en vrac que l’infrarouge moyen, il fournit des mesures meilleures et plus fiables sur une ligne de production.

Mesure d’humidité sans contact avec une grande précision

- Caractéristiques & Bénéfices

- Principales Applications

- Spécifications Techniques

- Données Techniques

- Installation de montage

- Téléchargement

- Mesure en ligne sans contact

- Non destructif pour tous les matériaux

- Conception robuste, IP69, température ambiante jusqu’à 80 °C

- Facultatif : Mesure de la température des matériaux

- Journaux à court et à long terme

- Mesure de l’humidité en pourcentage

- La surveillance continue IoT de l’état des capteurs augmente la disponibilité

- Ciment

- Chimie

- Asphalte

- Nourriture

- Verre

- Céréales

- Matériaux conducteurs

- Chaux

- Minéraux

- Acier

- Bois

- Fonderie

- Matériaux de construction

- Biomasse

- Recyclage

- Matériaux de construction

- Centrale électrique

| Spécifications Techniques | |

|---|---|

| Matériau sur mesure | Poussière, poudre, granulés et autres solides en vrac |

| Lieu à mesurer | Convoyeur à vis, convoyeur à bande, toboggan |

| Principe de fonctionnement | Spectographie NIR |

| Plage d’humidité | 0 à 95 % (selon l’application) |

| Température du matériau | Max. 400°C |

| Mesure de la température | Facultatif |

| Montage | Pôle |

| Sortie | 4…20mA, Modbus, Profinet |

| CAPTEUR | |

|---|---|

| Plage d’humidité | Min : 0,1 %, Max : 95 % (± 0,1%) |

| Température ambiante de fonctionnement | 0 – 80°C |

| Zone de mesure | 25 mm |

| Distance du produit | 20,3 – 40,6 cm |

| Taux d’échantillonnage | 60 calculs/seconde |

| Puissance | 90 – 260 V CA |

| Sorties | 2 x 4-20 mA, E/S discrètes en option |

| Boîtier/Poids | Aluminium / 5,4 kg |

| Certifications | CE, IP69 |

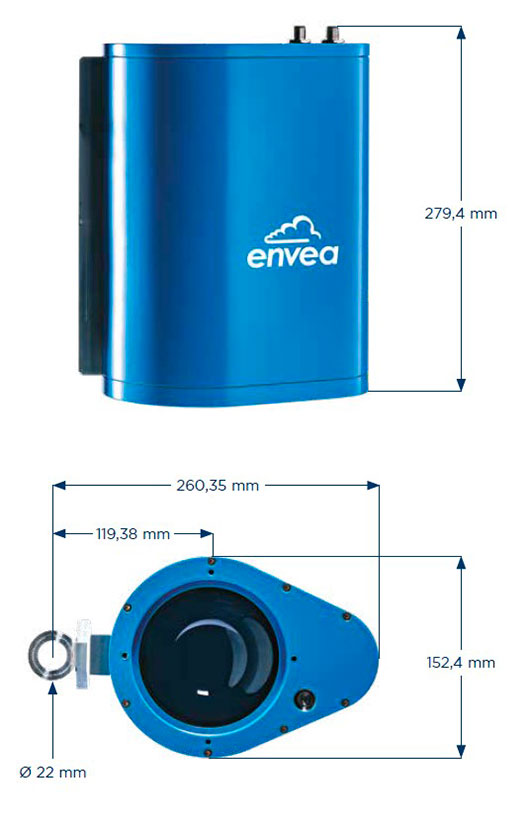

| Dimensions | 279,4 x 260,35 x 152,4 mm (H x L x L) |

| BASE DE DONNÉES & INTERFACES LOGICIELLES | |

|---|---|

| Facultatif Interfaces de bus |

Ethernet, Ethernet/IP, Profinet, Profibus-DP, Modbus-TCP/IP, Modbus RTU, RS485, DeviceNet |

| Logiciel | Application basée sur Windows, nécessite Win7 ou plus récent |

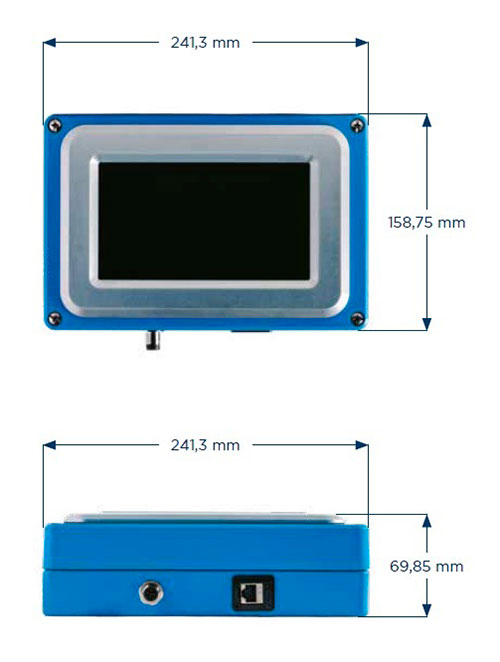

| AFFICHAGE OPÉRATEUR (EN OPTION) | |

|---|---|

| Affichage | Écran tactile capacitif couleur de 7 pouces |

| Puissance | 24 VCC |

| Câble | Ethernet |

| Boîtier/Poids | Aluminium / 1,8 kg |

| Fonctionnement ambiant température |

0 à 50˚C |

| Dimensions | 241,3 x 158,75 x 69,85 mm (L x L x H) |

| ACCESSOIRES (EN OPTION) | |

|---|---|

| Capteur de température | Mesure le matériau dans la plage de 0 à 400 °C |

| Fixation Opto-Port | Cette fixation en acier inoxydable permet au capteur de s’adapter à diverses situations telles que les convoyeurs à vis et les convoyeurs à chute libre. Peut être commandé avec un système de soufflage d’air pour les échantillons en chute libre. |

| Pare-poussière | Garantit que le capteur fournira des résultats cohérents et précis en empêchant l’accumulation de poussière et de crasse sur l’objectif |

| E/S discrètes OPTO 22 | Sortie pour les alarmes (LOP, HH, H, L, LL) |

Le capteur éclaire la surface du produit et, une fois que la lumière atteint le produit, les calculs permettant de mesurer les constituants nécessaires sont effectués. Des filtres et des détecteurs de cellules adaptés et optimisés pour les besoins spécifiques de votre application sont utilisés pour se concentrer sur le constituant exact mesuré afin de fournir les meilleurs résultats possibles.

La disponibilité et la fiabilité de ces données vous aident à minimiser les pertes de produits, à éliminer les temps d’arrêt inutiles et à augmenter l’efficacité de vos opérations, ce qui entraîne de meilleures marges et des bénéfices accrus.