Mesure des faibles débits de poudres et poussières

Parfaitement adapté pour contrôler et ajuster l’injection de réactif dans les lignes de traitement et de transport des fumées à très faible concentration de matière

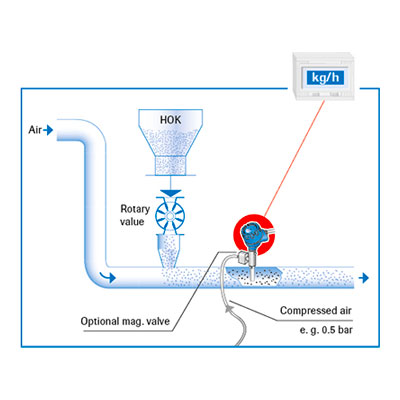

Capteur électrodynamique pour la mesure de faibles débits de 0 à 100 kg/h.

Pour des diamètres de conduite jusqu’à 1m.

Idéalement utilisé dans les transports en phase diluée.

En chute libre avec une vitesse de chute d’au moins 2 m/s.

- Adapté aux très faibles concentrations

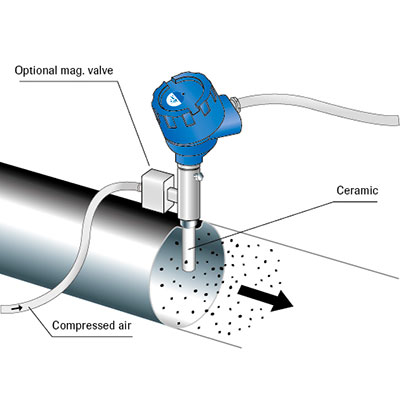

- Revêtement en céramique empêchant l’usure du capteur.

Mesure des faibles débits de matière solides de 0 … 100 kg/h

- Features & Benefits

- Main applications

- Technical Specifications

- Technical Data

- Mounting Installation

- Downloads

- Particularly good in pneumatic applications for material flow rates from a few g/h up to a few hundreds kg/h (depending on application)

- Very reliable for free-fall applications with a drop speed of at least 2 m/s (approx. 25 cm drop height)

- In cases where dust measuring instruments cannot cope and flow rate measuring instruments are overspecified

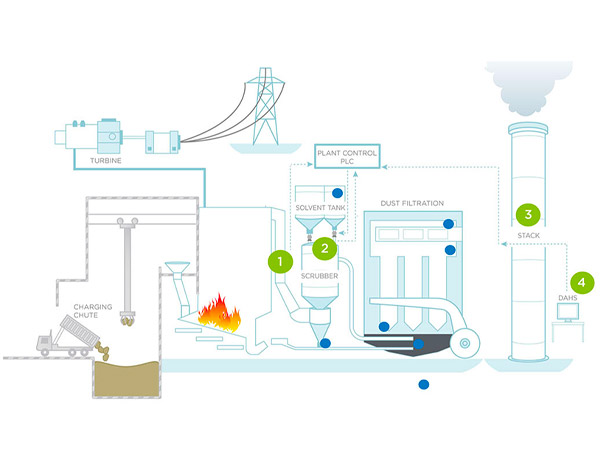

- The PicoFlow is perfectly suited for industrial applications especially in power generation or cement plants where it can be used to regulate or control additional reagent in flue gas treatment: injection of activated carbon, minsorb, lignite coke…

- Waste incineration

- Steel

- Chemistry

- Energy

- Cement

- Pharma

| Technical Specifications | |

|---|---|

| Material to measure | Dust, powders or granulates max. grain size 10 mm |

| Working principle | Electrodynamic |

| Process pressure | max. 10 bar |

| Process temperature | +150°C |

| Mounting | Via process connection |

| Type of Conveying | Pneumatic leanphase, vertical freefall after feeder |

| Flow rates | Depending on application |

| Pipe diameter | Max. 1000 mm |

| ATEX rating | Category 1/2 |

| Output | 4…20mA, Modbus, Profibus |

- Pneumatic conveying and free fall

- Absolute measurements in g/h or kg/h

- Materials: all types of dust, powder and granules

- Wear-resistent

| Sensor Technical Data | |

|---|---|

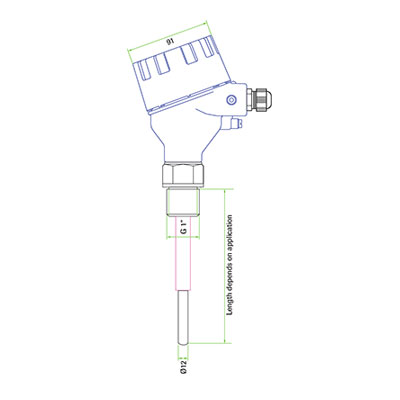

| Housing | Aluminium |

| Protection Type | IP 66; ATEX: Cat. 1/2 GD |

| Operation temperature | Process: -20 … +150 °C Ambient: -20 … + 60 °C |

| Max. working pressure | 10 bar |

| Weight | 1,5 kg |

| Sensor rod | Stainless steel, ceramic coated, max. 450 mm |

| Accuracy | ± 5 % in calibrated range |

| Transmitter Technical Data | ||||

|---|---|---|---|---|

| Transmitter (DIN Rail) | Transmitter (field housing) | |||

| Power supply | 24 V DC ±10 % | 110 / 230 V AC 50 Hz (optional 24 V DC) |

||

| Power consumption | 20 W / 24 VA | |||

| Protection type | IP 40 to EN 60 529 | IP 65 to EN 60 529/10.91 | ||

| Ambient operating temperature | -10 … +45 °C | |||

| Dimensions (W x H x D) | 23 x 90 x 118 mm | 258 x 237 x 174 mm | ||

| Weight | Approx. 172 g | Approx. 2.5 kg | ||

| Connection terminals cable cross-section |

0.2-2.5 mm2 [AWG 24-14] | |||

| Current output | 1 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

3 x 4 … 20 mA (0 … 20 mA), load < 500 Ω |

||

| Interface | RS 485 (ModBus RTU) / USB | |||

| Pulse output | Open collector – max. 30 V, 20 mA | |||

| Relay contact | Max. rated load: 250 V AC Max. peak current: 6 A Max. rated load 230 V AC: 250 VA Max. breaking capacity DC1: 3/110/220 V: 3/0.35/0.2 A Min. switching load: 500 mW (10 V / 5 mA) |

|||

| Data backup | Flash memory | |||

| The PicoFlow can be installed in metallic ducts and pipelines.

It should be installed as far as possible away from curves and other fittings such as valves and slides. The distance between the sensor rod and fittings in the duct should be at least three times the duct diameter in every flow direction. Non-metallic ducts must be cased with a metal sleeve, a metal foil or a tight-mesh metal grille over a length of at least five times the duct diameter. |

|